Posted in this story is a very interesting PDF available for download here for a 1975 U.S. Patent issued to Donald K. Werle, Romas Kasparas, Sidney Katz, assigned through the U.S. Navy, that describes a dispersion method for a “powder contrail.”

As other researchers have also pointed out, the Powder Contrail Generation patent document could be a useful clue into the true agenda and purpose of the “chemtrail” phenomenon, which is clearly tied to almost a century of man-made weather manipulation. Already, it is admitted that the government has experimented with geo-engineering, which is says would help reflect heat and combat phony global warming / climate change.

It also references 5 other patents that deal with aviation fuel dispersants that go back to the 1920s. It further references the “chaff” application, as to create a radar jamming reflective screen, and other potential applications, including the use of numerous other powder formulas.

• March 1, 1927 Patent #1619183 by Bradner and Olgesby for the Process of Producing Smoke Clouds from Moving Aircraft

• June 30, 1936 Patent# 2045865 by Glen H. Morey and assigned by Phillips Petroleum forSkywriting Apparatus

• April 8, 1952 Patent# 2591988 by Oswin B. Willcox and assigned to “Pont DU” (a.k.a. DuPont?) for Process for producing improved tio2 titanium pigments

•See Also: April 8, 1969 Patent# 3437502 by Alfred J. Werner and assigned to “Pont DU” forTITANIUM DIOXIDE PIGMENT COATED WITH SILICA AND ALUMINA

• September 29, 1970 Patent# 3531310 by Neil C. Goodspeed, Russell R. May Jr. and Joseph Ross assigned to PPG Industries for PRODUCTION OF IMPROVED METAL OXIDE PIGMENT

• February 1924 Patent# R15771 by Savage

• March 1966 Patent# 1022621 in United Kingdom

• June 30, 1936 Patent# 2045865 by Glen H. Morey and assigned by Phillips Petroleum forSkywriting Apparatus

• April 8, 1952 Patent# 2591988 by Oswin B. Willcox and assigned to “Pont DU” (a.k.a. DuPont?) for Process for producing improved tio2 titanium pigments

•See Also: April 8, 1969 Patent# 3437502 by Alfred J. Werner and assigned to “Pont DU” forTITANIUM DIOXIDE PIGMENT COATED WITH SILICA AND ALUMINA

• September 29, 1970 Patent# 3531310 by Neil C. Goodspeed, Russell R. May Jr. and Joseph Ross assigned to PPG Industries for PRODUCTION OF IMPROVED METAL OXIDE PIGMENT

• February 1924 Patent# R15771 by Savage

• March 1966 Patent# 1022621 in United Kingdom

——–

Download PDF

S3899144: Powder contrail generation

Inventors:

Werle; Donald K. , Hillside, IL

Kasparas; Romas , Riverside, IL

Katz; Sidney , Chicago, IL

Werle; Donald K. , Hillside, IL

Kasparas; Romas , Riverside, IL

Katz; Sidney , Chicago, IL

Applicants:

The United States of America as represented by the Secretary of the Navy, Washington, DC

The United States of America as represented by the Secretary of the Navy, Washington, DC

Appplication #:

US1974000490610

US1974000490610

Date of Issue:

Aug. 12, 1975 / July 22, 1974

Aug. 12, 1975 / July 22, 1974

Abstract:

Light scattering pigment powder particles, surface treated to minimize inparticle cohesive forces, are dispensed from a jet mill deagglomerator as separate single particles to produce a powder contrail having maximum visibility or radiation scattering ability for a given weight material.

Light scattering pigment powder particles, surface treated to minimize inparticle cohesive forces, are dispensed from a jet mill deagglomerator as separate single particles to produce a powder contrail having maximum visibility or radiation scattering ability for a given weight material.

What claim is:

1. Contrail generation apparatus for producing a powder contrail having maximum radiation scattering ability for a given weight material, comprising: a. an aerodynamic housing;

b. a jet tube means passing through said housing, said tube means having an inlet at a forward end of said housing and an exhaust at a rearward end thereof;

c. a powder storage means in said housing;

d. a deagglomeration means also in said housing; e. means connecting said powder storage means with said deagglomeration means for feeding radiation scattering powder from said powder storage means to said deagglomeration means;

f. the output of said deagglomeration means dispensing directly into said jet tube means for exhausting deagglomerated powder particles into the atmosphere to form a contrail; and h. means for controlling the flow of said powder from said storage means to said deagglomeration means.

2. Apparatus as in claim 1 wherein said jet tube means is a ram air jet tube.

3. Apparatus as in claim 1 wherein an upstream deflector baffle is provided at the output of said deagglomeration means into said jet tube means to produce a venturi effect for minimizing back pressure on said powder feeding means.

4. Apparatus as in claim 1 wherein said deagglomerator means comprises: a. means for subjecting powder particles from said powder storage means to a hammering action to aerate and precondition the powder; and b. a jet mill means to further deagglomerate the powder into separate particles.

5. Apparatus as in claim 4 wherein pressurized gas means is provided for operating said deagglomeration means.

6. Apparatus as in claim 1 wherein said radiation scattering powder particles are titanium dioxide pigment having a median particle size of about 0.3 microns.

7. Apparatus as in claim 1 wherein said radiation scattering powder particles have a coating of extremely fine hydrophobic colloidal silica thereon to minimize interparticle cohesive forces.

8. Apparatus as in claim 1 wherein the formulation of said powder consists of 85% by weight of TiO2 pigment of approximately 0.3 micron media particle size, 10% by weight of colloidal silica of 0.007 micron primary particle size, and 5% by weight of silica gel having an average particle size of 4.5 microns.

9. The method of producing a light radiation scattering contrail, comprising:

a. surface treating light scattering powder particles to minimize interparticle cohesive forces;

b. deagglomerating said powder particles in two stages prior to dispensing into a jet tube by subjecting said powder particles to a hammering action in the first stage to aerate and precondition the powder, and by passing said powder through a jet mill in the second stage to further deagglomerate the powder;

c. dispensing the deagglomerated powder from the jet mill directly into a jet tube for exhausting said powder into the atmosphere, thus forming a contrail.

10. A method as in claim 9 wherein said light scattering powder particles is titanium dioxide pigment.

11. A method as in claim 9 wherein said powder particles are treated with a coating of extremely fine hydrophobic colloidal silica to minimize interparticle cohesive forces.

12. A method as in claim 11 wherein said treated powder particles are further protected with a silica gel powder.

DESCRIPTION OF PREFERRED EMBODIMENT

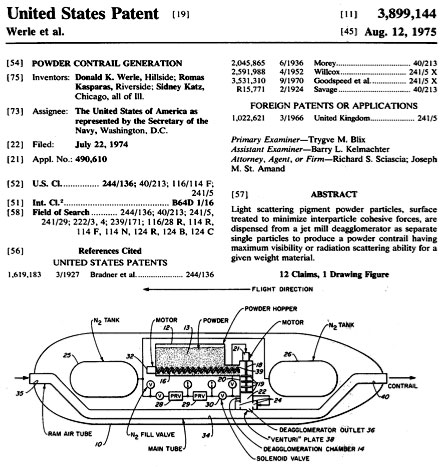

The powder contail generator in pod 10, shown in FIG. 1, is provided with a powder feed hopper 12 positioned in the center section of the pod and which feeds a powder 13 to a deagglomerator 14 by means of screw conveyors 16 across the bottom of the hopper. The deagglomerator 14 produces two stages of action. In the first stage of deagglomeration, a shaft 18 having projecting radial rods 19 in compartment 20 is rotated by an air motor 21, or other suitable drive means. The shaft 18 is rotated at about 10,000 rpm, for example. As powder 13 descends through the first stage compartment 20 of the deagglomeration chamber, the hammering action of rotating rods 19 serves to aerate and precondition the powder before the second stage of deagglomeration takes place in the jet mill section 22. In the jet mill 22, a plurality of radial jets 24 (e.g., six 0.050 inch diamter radial jets) direct nitrogen gas (at e.g., 120 psig) inward to provide energy for further deagglomeration of the powder. The N2, or other suitable gas, is provided from storage tanks 25 and 26, for example, in the pod.

The jet mill 22 operates in a similar manner to commercial fluid energy mills except that there is no provision for recirculation of oversize particles. Tests with the deagglomerator show that at a feed rate of approximately 11/2 lb/min, treated titanium dioxide powder pigment is effectively dispersed as single particles with very few agglomerates evident.

Air enters ram air tube 34 at its entrance 35 and the exhaust from the jet mill deagglomerator passes directly into the ram air tube. At the deagglomerator exhaust 36 into ram air tube 34, an upstream deflector baffle 38 produces a venturi effect which minimizes back pressure on the powder feed system. The powder is then jetted from the exhaust end 40 of the ram air tube to produce a contrail. A pressure equalization tube, not shown, can be used to connect the top of the closed hopper 12 to the deagglomeration chamber 14. A butterfly valve could be provided at the powder hopper outlet 39 to completely isolate and seal off the powder supply when not in use. Powder 13 could then be stored in hopper 12 for several weeks, without danger of picking up excessive moisture, and still be adequately dispensed.

Preparation of the light scatter powder 13 is of a critical importance to production of a powder “contrail” having maximum visibility for a given weight of material. It is essential that the pigment powder particles be dispensed as separate single particles rather than as agglomerates of two or more particles. The powder treatment produces the most easily dispersed powder through the use of surface treatments which minimize interparticle cohesive forces.

Titanium dioxide pigment was selected as the primary light scattering material because of its highly efficient light scattering ability and commercially available pigment grades. Titanium dioxide pigment (e.g., DuPont R–931) with a median particle size of about 0.3u has a high bulk density and is not readily aerosolizable as a submicron cloud without the consumption of a large amount of deagglomeration energy. In order to reduce the energy requirement for deagglomeration, the TiO2 powder is specially treated with a hydrophobic colloidal silica which coats and separates the individual TiO2 pigment particles. The extremely fine particulate nature (0.007u primary particle size) of Cobot S–101 Silanox grade, for example, of colloidal silica minimizes the amount needed to coat and separate the TiO2 particles, and the hydrophobic surface minimizes the affinity of the powder for absorbtion of moisture from the atmosphere. Adsorbed moisture in powders causes liquid bridges at interparticle contacts and it then becomes necessary to overcome the adsorbed-liquid surface tension forces as well as the weaker Van der Waals’ forces before the particles can be separated.

The Silanox treated titanium dioxide pigment is further protected from the deleterious effects of adsorbed moisture by incorporation of silica gel. The silica gel preferentially adsorbs water vapor that the powder may be exposed to after drying and before use. The silica gel used is a powder product, such as Syloid 65 from the W. R Grace and Co., Davison Chemical Division, and has an average particle size about 4.5u and a large capacity for moisture at low humidities.

A typical powder composition used is shown in Table 1. This formulation was blended intimately with a Patterson-Kelley Co. twin shell dry LB-model LB–2161 with intensifier. Batches of 1500 g were blended for 15 min. each and packaged in 5-lb cans. The bulk density of the blended powder is 0.22 g/cc. Since deagglomeration is facilitated by having the powder bone dry, the powder should be predried before sealing the cans. In view of long periods (e.g., about 4 months) between powder preparation and use it is found preferable to spread the powder in a thin layer in an open container and place in a 400*F over two days before planned usage. The powder is removed and placed in the hopper about 2 hours before use.

Table 1 ______________________________________ CONTRAIL POWDER FORMULATION Ingredient % by Weight ______________________________________ TiO2 (e.g., DuPont R-931) 85 median particle size 0.3u Colloidal Silica (e.g., Cabot S-101 Silanox) 10 primary particle size 0.007u Silica gel (e.g., Syloid 65) 5 average particle size 4.5u ______________________________________ Other type powder compositions can also be used with the apparatus described herein. For example, various powder particles which reflect electromagnetic radiation can be dispensed as a chaff or the like from the contrail generator.

Obviously many modifications and variations of the present invention are possible in the light of the above teachings. It is therefore to be understood that within the scope of the appended claims the invention may be practiced otherwise than as specifically described.

BACKGROUND

The present invention relates to method and apparatus for contrail generation and the like.

An earlier known method in use for contrail generation involves oil smoke trails produced by injecting liquid oil directly into the hot jet exhaust of an aircraft target vehicle. The oil vaporizes and recondenses being the aircraft producing a brilliant white trail. Oil smoke trail production requires a minimum of equipment; and, the material is low in cost and readily available. However, oil smoke requires a heat source to vaporize the liquid oil and not all aircraft target vehicles, notably towed targets, have such a heat source. Also, at altitudes above about 25,000 feet oil smoke visibility degrades rapidly.

SUMMARY

The present invention is for a powder generator requiring no heat source to emit a “contrail” with sufficient visibility to aid in visual acquisition of an aircraft target vehicle and the like. The term “contrail” was adopted for convenience in identifying the visible powder trail of this invention. Aircraft target vehicles are used to simulate aerial threats for missile tests and often fly at altitudes between 5,000 and 20,000 feet at speeds of 300 and 400 knots or more. The present invention is also suitable for use in other aircraft vehicles to generate contrails or reflective screens for any desired purpose.

The powder contail generator is normally carried on an aircraft in a pod containing a ram air tube and powder feed hopper. Powder particles, surface treated to minimize interparticle cohesive forces are fed from the hopper to a deagglomerator and then to the ram air tube for dispensing as separate single particles to produce a contrail having maximum visibility for a given weight material.

Other object, advantages and novel features of the invention will become apparent from the following detailed description of the invention when considered in conjunction with the accompanying drawing.

Chemtrails: The List of Patents For Stratospheric Aerial Spraying Programs

Here is a long list of other patents related to atmospheric or weather manipulation posted by Neil Foster of the Sovereign Independent:

United States Patent and Trademark Office

1338343 – April 27, 1920 – Process And Apparatus For The Production of Intense Artificial Clouds, Fogs, or Mists

1619183 – March 1, 1927 – Process of Producing Smoke Clouds From Moving Aircraft

1631753 – June 7, 1927 – Electric Heater – Referenced in 3990987

1665267 – April 10, 1928 – Process of Producing Artificial Fogs

1892132 – December 27, 1932 – Atomizing Attachment For Airplane Engine Exhausts

1928963 – October 3, 1933 – Electrical System And Method

1957075 – May 1, 1934 – Airplane Spray Equipment

2097581 – November 2, 1937 – Electric Stream Generator – Referenced in 3990987

2409201 – October 15, 1946 – Smoke Producing Mixture

2476171 – July 18, 1945 – Smoke Screen Generator

2480967 – September 6, 1949 – Aerial Discharge Device

2550324 – April 24, 1951 – Process For Controlling Weather

2510867 – October 9, 1951 – Method of Crystal Formation and Precipitation

2582678 – June 15, 1952 – Material Disseminating Apparatus For Airplanes

2591988 – April 8, 1952 – Production of TiO2 Pigments – Referenced in 3899144

2614083 – October 14, 1952 – Metal Chloride Screening Smoke Mixture

2633455 – March 31, 1953 – Smoke Generator

2688069 – August 31, 1954 – Steam Generator – Referenced in 3990987

2721495 – October 25, 1955 – Method And Apparatus For Detecting Minute Crystal Forming Particles Suspended in a Gaseous Atmosphere

2730402 – January 10, 1956 – Controllable Dispersal Device

2801322 – July 30, 1957 – Decomposition Chamber for Monopropellant Fuel – Referenced in 3990987

2881335 – April 7, 1959 – Generation of Electrical Fields

2908442 – October 13, 1959 – Method For Dispersing Natural Atmospheric Fogs And Clouds

2986360 – May 30, 1962 – Aerial Insecticide Dusting Device

2963975 – December 13, 1960 – Cloud Seeding Carbon Dioxide Bullet

3126155 – March 24, 1964 – Silver Iodide Cloud Seeding Generator – Referenced in 3990987

3127107 – March 31, 1964 – Generation of Ice-Nucleating Crystals

3131131 – April 28, 1964 – Electrostatic Mixing in Microbial Conversions

3174150 – March 16, 1965 – Self-Focusing Antenna System

3234357 – February 8, 1966 – Electrically Heated Smoke Producing Device

3274035 – September 20, 1966 – Metallic Composition For Production of Hydroscopic Smoke

3300721 – January 24, 1967 – Means For Communication Through a Layer of Ionized Gases

3313487 – April 11, 1967 – Cloud Seeding Apparatus

3338476 – August 29, 1967 – Heating Device For Use With Aerosol Containers – Referenced in 3990987

3410489 – November 12, 1968 – Automatically Adjustable Airfoil Spray System With Pump

3429507 – February 25, 1969 – Rainmaker

3432208 – November 7, 1967 – Fluidized Particle Dispenser

3441214 – April 29, 1969 – Method And Apparatus For Seeding Clouds

3445844 – May 20, 1969 – Trapped Electromagnetic Radiation Communications System

3456880 – July 22, 1969 – Method Of Producing Precipitation From The Atmosphere

3518670 June 30, 1970 – Artificial Ion Cloud

3534906 – October 20, 1970 – Control of Atmospheric Particles

3545677 – December 8, 1970 – Method of Cloud Seeding

3564253 – February 16, 1971 – System And Method For Irradiation Of Planet Surface Areas

3587966 – June 28, 1971 – Freezing Nucleation

3601312 – August 24, 1971 – Methods of Increasing The Likelihood oF Precipatation By The Artificial Introduction Of Sea Water Vapor Into The Atmosphere Winward Of An Air Lift Region

3608810 – September 28, 1971 – Methods of Treating Atmospheric Conditions

3608820 – September 20, 1971 – Treatment of Atmospheric Conditions by Intermittent Dispensing of Materials Therein

3613992 – October 19, 1971 – Weather Modification Method

3630950 – December 28, 1971 – Combustible Compositions For Generating Aerosols, Particularly Suitable For Cloud Modification And Weather Control And Aerosolization Process

USRE29142 – This patent is a reissue of patent US3630950 – Combustible compositions for generating aerosols, particularly suitable for cloud modification and weather control and aerosolization process

3659785 – December 8, 1971 – Weather Modification Utilizing Microencapsulated Material

3666176 – March 3, 1972 – Solar Temperature Inversion Device

3677840 – July 18, 1972 – Pyrotechnics Comprising Oxide of Silver For Weather Modification Use

3722183 – March 27, 1973 – Device For Clearing Impurities From The Atmosphere

3769107 – October 30, 1973 – Pyrotechnic Composition For Generating Lead Based Smoke

3784099 – January 8, 1974 – Air Pollution Control Method

3785557 – January 15, 1974 – Cloud Seeding System

3795626 – March 5, 1974 – Weather Modification Process

3808595 – April 30, 1974 – Chaff Dispensing System

3813875 – June 4, 1974 – Rocket Having Barium Release System to Create Ion Clouds In The Upper Atmopsphere

3835059 – September 10, 1974 – Methods of Generating Ice Nuclei Smoke Particles For Weather Modification And Apparatus Therefore

3835293 – September 10, 1974 – Electrical Heating Aparatus For Generating Super Heated Vapors – Referenced in 3990987

3877642 – April 15, 1975 – Freezing Nucleant

3882393 – May 6, 1975 – Communications System Utilizing Modulation of The Characteristic Polarization of The Ionosphere

3896993 – July 29, 1975 – Process For Local Modification of Fog And Clouds For Triggering Their Precipitation And For Hindering The Development of Hail Producing Clouds

3899129 – August 12, 1975 – Apparatus for generating ice nuclei smoke particles for weather modification

3899144 – August 12, 1975 – Powder contrail generation

3940059 – February 24, 1976 – Method For Fog Dispersion

3940060 – February 24, 1976 – Vortex Ring Generator

3990987 – November 9, 1976 – Smoke generator

3992628 – November 16, 1976 – Countermeasure system for laser radiation

3994437 – November 30, 1976 – Broadcast dissemination of trace quantities of biologically active chemicals

4042196 – August 16, 1977 – Method and apparatus for triggering a substantial change in earth characteristics and measuring earth changes

RE29,142 – February 22, 1977 – Reissue of: 03630950 – Combustible compositions for generating aerosols, particularly suitable for cloud modification and weather control and aerosolization process

4035726 – July 12, 1977 – Method of controlling and/or improving high-latitude and other communications or radio wave surveillance systems by partial control of radio wave et al

4096005 – June 20, 1978 – Pyrotechnic Cloud Seeding Composition

4129252 – December 12, 1978 – Method and apparatus for production of seeding materials

4141274 – February 27, 1979 – Weather modification automatic cartridge dispenser

4167008 – September 4, 1979 – Fluid bed chaff dispenser

4347284 – August 31, 1982 – White cover sheet material capable of reflecting ultraviolet rays

4362271 – December 7, 1982 – Procedure for the artificial modification of atmospheric precipitation as well as compounds with a dimethyl sulfoxide base for use in carrying out said procedure

4402480 – September 6, 1983 – Atmosphere modification satellite

4412654 – November 1, 1983 – Laminar microjet atomizer and method of aerial spraying of liquids

4415265 – November 15, 1983 – Method and apparatus for aerosol particle absorption spectroscopy

4470544 – September 11, 1984 – Method of and Means for weather modification

4475927 – October 9, 1984 – Bipolar Fog Abatement System

4600147 – July 15, 1986 – Liquid propane generator for cloud seeding apparatus

4633714 – January 6, 1987 – Aerosol particle charge and size analyzer

4643355 – February 17, 1987 – Method and apparatus for modification of climatic conditions

4653690 – March 31, 1987 – Method of producing cumulus clouds

4684063 – August 4, 1987 – Particulates generation and removal

4686605 – August 11, 1987 – Method and apparatus for altering a region in the earth’s atmosphere, ionosphere, and/or magnetosphere

4704942 – November 10, 1987 – Charged Aerosol

4712155 – December 8, 1987 – Method and apparatus for creating an artificial electron cyclotron heating region of plasma

4744919 – May 17, 1988 – Method of dispersing particulate aerosol tracer

4766725 – August 30, 1988 – Method of suppressing formation of contrails and solution therefor

4829838 – May 16, 1989 – Method and apparatus for the measurement of the size of particles entrained in a gas

4836086 – June 6, 1989 – Apparatus and method for the mixing and diffusion of warm and cold air for dissolving fog

4873928 – October 17, 1989 – Nuclear-sized explosions without radiation

4948257 – August 14, 1990 – Laser optical measuring device and method for stabilizing fringe pattern spacing

48050 – August 14, 1990 – Liquid atomizing a94pparatus for aerial spraying

4999637 – March 12, 1991 – Creation of artificial ionization clouds above the earth

5003186 – March 26, 1991 – Stratospheric Welsbach seeding for reduction of global warming

5005355 – April 9, 1991 – Method of suppressing formation of contrails and solution therefor

5038664 – August 13, 1991 – Method for producing a shell of relativistic particles at an altitude above the earths surface

5041760 – August 20, 1991 – Method and apparatus for generating and utilizing a compound plasma configuration

5041834 – August 20, 1991 – Artificial ionospheric mirror composed of a plasma layer which can be tilted

5056357 – October 15, 1991- Acoustic method for measuring properties of a mobile medium

5059909 – October 22, 1991 – Determination of particle size and electrical charge

5104069 – April 14, 1992 – Apparatus and method for ejecting matter from an aircraft

5110502 – May 5, 1992 – Method of suppressing formation of contrails and solution therefor

5156802 – October 20, 1992 – Inspection of fuel particles with acoustics

5174498 – December 29, 1992 – Cloud Seeding

5148173 – September 15, 1992 – Millimeter wave screening cloud and method

5245290 – September 14, 1993 – Device for determining the size and charge of colloidal particles by measuring electroacoustic effect

5286979 – February 15, 1994 – Process for absorbing ultraviolet radiation using dispersed melanin

5296910 – March 22, 1994 – Method and apparatus for particle analysis

5327222 – July 5, 1994 – Displacement information detecting apparatus

5357865 – October 25, 1994 – Method of cloud seeding

5360162 – November 1, 1994 – Method and composition for precipitation of atmospheric water

5383024 – January 17, 1995 – Optical wet steam monitor

5425413 – June 20, 1995 – Method to hinder the formation and to break-up overhead atmospheric inversions, enhance ground level air circulation and improve urban air quality

5434667 – July 18, 1995 – Characterization of particles by modulated dynamic light scattering

5441200 – August 15, 1995 – Tropical cyclone disruption

5486900 – January 23, 1996 – Measuring device for amount of charge of toner and image forming apparatus having the measuring device

5556029 – September 17, 1996 – Method of hydrometeor dissipation (clouds)

5628455 – May 13, 1997 – Method and apparatus for modification of supercooled fog

5631414 – May 20, 1997 – Method and device for remote diagnostics of ocean-atmosphere system state

5639441 – June 17, 1997 – Methods for fine particle formation

5762298 – June 9, 1998 – Use of artificial satellites in earth orbits adaptively to modify the effect that solar radiation would otherwise have on earth’s weather

5912396 – June 15, 1999 – System and method for remediation of selected atmospheric conditions

5922976 – July 13, 1999 – Method of measuring aerosol particles using automated mobility-classified aerosol detector

5949001 – September 7, 1999 – Method for aerodynamic particle size analysis

5984239 – November 16, 1999 – Weather modification by artificial satellite

6025402 – February 15, 2000 – Chemical composition for effectuating a reduction of visibility obscuration, and a detoxifixation of fumes and chemical fogs in spaces of fire origin

6030506 – February 29, 2000 – Preparation of independently generated highly reactive chemical species

6034073 – March 7, 2000 – Solvent detergent emulsions having antiviral activity

6045089 – April 4, 2000 – Solar-powered airplane

6056203 – May 2, 2000 – Method and apparatus for modifying supercooled clouds

6110590 – August 29, 2000 – Synthetically spun silk nanofibers and a process for making the same

6263744 – July 24, 2001 – Automated mobility-classified-aerosol detector

6281972 – August 28, 2001 – Method and apparatus for measuring particle-size distribution

6315213 – November 13, 2001 – Method of modifying weather

6382526 – May 7, 2002 – Process and apparatus for the production of nanofibers

6408704 – June 25, 2002 – Aerodynamic particle size analysis method and apparatus

6412416 – July 2, 2002 – Propellant-based aerosol generation devices and method

6520425 – February 18, 2003 – Process and apparatus for the production of nanofibers

6539812 – April 1, 2003 – System for measuring the flow-rate of a gas by means of ultrasound

6553849 – April 29, 2003 – Electrodynamic particle size analyzer

6569393 – May 27, 2003 – Method and device for cleaning the atmosphere

1338343 – April 27, 1920 – Process And Apparatus For The Production of Intense Artificial Clouds, Fogs, or Mists

1619183 – March 1, 1927 – Process of Producing Smoke Clouds From Moving Aircraft

1631753 – June 7, 1927 – Electric Heater – Referenced in 3990987

1665267 – April 10, 1928 – Process of Producing Artificial Fogs

1892132 – December 27, 1932 – Atomizing Attachment For Airplane Engine Exhausts

1928963 – October 3, 1933 – Electrical System And Method

1957075 – May 1, 1934 – Airplane Spray Equipment

2097581 – November 2, 1937 – Electric Stream Generator – Referenced in 3990987

2409201 – October 15, 1946 – Smoke Producing Mixture

2476171 – July 18, 1945 – Smoke Screen Generator

2480967 – September 6, 1949 – Aerial Discharge Device

2550324 – April 24, 1951 – Process For Controlling Weather

2510867 – October 9, 1951 – Method of Crystal Formation and Precipitation

2582678 – June 15, 1952 – Material Disseminating Apparatus For Airplanes

2591988 – April 8, 1952 – Production of TiO2 Pigments – Referenced in 3899144

2614083 – October 14, 1952 – Metal Chloride Screening Smoke Mixture

2633455 – March 31, 1953 – Smoke Generator

2688069 – August 31, 1954 – Steam Generator – Referenced in 3990987

2721495 – October 25, 1955 – Method And Apparatus For Detecting Minute Crystal Forming Particles Suspended in a Gaseous Atmosphere

2730402 – January 10, 1956 – Controllable Dispersal Device

2801322 – July 30, 1957 – Decomposition Chamber for Monopropellant Fuel – Referenced in 3990987

2881335 – April 7, 1959 – Generation of Electrical Fields

2908442 – October 13, 1959 – Method For Dispersing Natural Atmospheric Fogs And Clouds

2986360 – May 30, 1962 – Aerial Insecticide Dusting Device

2963975 – December 13, 1960 – Cloud Seeding Carbon Dioxide Bullet

3126155 – March 24, 1964 – Silver Iodide Cloud Seeding Generator – Referenced in 3990987

3127107 – March 31, 1964 – Generation of Ice-Nucleating Crystals

3131131 – April 28, 1964 – Electrostatic Mixing in Microbial Conversions

3174150 – March 16, 1965 – Self-Focusing Antenna System

3234357 – February 8, 1966 – Electrically Heated Smoke Producing Device

3274035 – September 20, 1966 – Metallic Composition For Production of Hydroscopic Smoke

3300721 – January 24, 1967 – Means For Communication Through a Layer of Ionized Gases

3313487 – April 11, 1967 – Cloud Seeding Apparatus

3338476 – August 29, 1967 – Heating Device For Use With Aerosol Containers – Referenced in 3990987

3410489 – November 12, 1968 – Automatically Adjustable Airfoil Spray System With Pump

3429507 – February 25, 1969 – Rainmaker

3432208 – November 7, 1967 – Fluidized Particle Dispenser

3441214 – April 29, 1969 – Method And Apparatus For Seeding Clouds

3445844 – May 20, 1969 – Trapped Electromagnetic Radiation Communications System

3456880 – July 22, 1969 – Method Of Producing Precipitation From The Atmosphere

3518670 June 30, 1970 – Artificial Ion Cloud

3534906 – October 20, 1970 – Control of Atmospheric Particles

3545677 – December 8, 1970 – Method of Cloud Seeding

3564253 – February 16, 1971 – System And Method For Irradiation Of Planet Surface Areas

3587966 – June 28, 1971 – Freezing Nucleation

3601312 – August 24, 1971 – Methods of Increasing The Likelihood oF Precipatation By The Artificial Introduction Of Sea Water Vapor Into The Atmosphere Winward Of An Air Lift Region

3608810 – September 28, 1971 – Methods of Treating Atmospheric Conditions

3608820 – September 20, 1971 – Treatment of Atmospheric Conditions by Intermittent Dispensing of Materials Therein

3613992 – October 19, 1971 – Weather Modification Method

3630950 – December 28, 1971 – Combustible Compositions For Generating Aerosols, Particularly Suitable For Cloud Modification And Weather Control And Aerosolization Process

USRE29142 – This patent is a reissue of patent US3630950 – Combustible compositions for generating aerosols, particularly suitable for cloud modification and weather control and aerosolization process

3659785 – December 8, 1971 – Weather Modification Utilizing Microencapsulated Material

3666176 – March 3, 1972 – Solar Temperature Inversion Device

3677840 – July 18, 1972 – Pyrotechnics Comprising Oxide of Silver For Weather Modification Use

3722183 – March 27, 1973 – Device For Clearing Impurities From The Atmosphere

3769107 – October 30, 1973 – Pyrotechnic Composition For Generating Lead Based Smoke

3784099 – January 8, 1974 – Air Pollution Control Method

3785557 – January 15, 1974 – Cloud Seeding System

3795626 – March 5, 1974 – Weather Modification Process

3808595 – April 30, 1974 – Chaff Dispensing System

3813875 – June 4, 1974 – Rocket Having Barium Release System to Create Ion Clouds In The Upper Atmopsphere

3835059 – September 10, 1974 – Methods of Generating Ice Nuclei Smoke Particles For Weather Modification And Apparatus Therefore

3835293 – September 10, 1974 – Electrical Heating Aparatus For Generating Super Heated Vapors – Referenced in 3990987

3877642 – April 15, 1975 – Freezing Nucleant

3882393 – May 6, 1975 – Communications System Utilizing Modulation of The Characteristic Polarization of The Ionosphere

3896993 – July 29, 1975 – Process For Local Modification of Fog And Clouds For Triggering Their Precipitation And For Hindering The Development of Hail Producing Clouds

3899129 – August 12, 1975 – Apparatus for generating ice nuclei smoke particles for weather modification

3899144 – August 12, 1975 – Powder contrail generation

3940059 – February 24, 1976 – Method For Fog Dispersion

3940060 – February 24, 1976 – Vortex Ring Generator

3990987 – November 9, 1976 – Smoke generator

3992628 – November 16, 1976 – Countermeasure system for laser radiation

3994437 – November 30, 1976 – Broadcast dissemination of trace quantities of biologically active chemicals

4042196 – August 16, 1977 – Method and apparatus for triggering a substantial change in earth characteristics and measuring earth changes

RE29,142 – February 22, 1977 – Reissue of: 03630950 – Combustible compositions for generating aerosols, particularly suitable for cloud modification and weather control and aerosolization process

4035726 – July 12, 1977 – Method of controlling and/or improving high-latitude and other communications or radio wave surveillance systems by partial control of radio wave et al

4096005 – June 20, 1978 – Pyrotechnic Cloud Seeding Composition

4129252 – December 12, 1978 – Method and apparatus for production of seeding materials

4141274 – February 27, 1979 – Weather modification automatic cartridge dispenser

4167008 – September 4, 1979 – Fluid bed chaff dispenser

4347284 – August 31, 1982 – White cover sheet material capable of reflecting ultraviolet rays

4362271 – December 7, 1982 – Procedure for the artificial modification of atmospheric precipitation as well as compounds with a dimethyl sulfoxide base for use in carrying out said procedure

4402480 – September 6, 1983 – Atmosphere modification satellite

4412654 – November 1, 1983 – Laminar microjet atomizer and method of aerial spraying of liquids

4415265 – November 15, 1983 – Method and apparatus for aerosol particle absorption spectroscopy

4470544 – September 11, 1984 – Method of and Means for weather modification

4475927 – October 9, 1984 – Bipolar Fog Abatement System

4600147 – July 15, 1986 – Liquid propane generator for cloud seeding apparatus

4633714 – January 6, 1987 – Aerosol particle charge and size analyzer

4643355 – February 17, 1987 – Method and apparatus for modification of climatic conditions

4653690 – March 31, 1987 – Method of producing cumulus clouds

4684063 – August 4, 1987 – Particulates generation and removal

4686605 – August 11, 1987 – Method and apparatus for altering a region in the earth’s atmosphere, ionosphere, and/or magnetosphere

4704942 – November 10, 1987 – Charged Aerosol

4712155 – December 8, 1987 – Method and apparatus for creating an artificial electron cyclotron heating region of plasma

4744919 – May 17, 1988 – Method of dispersing particulate aerosol tracer

4766725 – August 30, 1988 – Method of suppressing formation of contrails and solution therefor

4829838 – May 16, 1989 – Method and apparatus for the measurement of the size of particles entrained in a gas

4836086 – June 6, 1989 – Apparatus and method for the mixing and diffusion of warm and cold air for dissolving fog

4873928 – October 17, 1989 – Nuclear-sized explosions without radiation

4948257 – August 14, 1990 – Laser optical measuring device and method for stabilizing fringe pattern spacing

48050 – August 14, 1990 – Liquid atomizing a94pparatus for aerial spraying

4999637 – March 12, 1991 – Creation of artificial ionization clouds above the earth

5003186 – March 26, 1991 – Stratospheric Welsbach seeding for reduction of global warming

5005355 – April 9, 1991 – Method of suppressing formation of contrails and solution therefor

5038664 – August 13, 1991 – Method for producing a shell of relativistic particles at an altitude above the earths surface

5041760 – August 20, 1991 – Method and apparatus for generating and utilizing a compound plasma configuration

5041834 – August 20, 1991 – Artificial ionospheric mirror composed of a plasma layer which can be tilted

5056357 – October 15, 1991- Acoustic method for measuring properties of a mobile medium

5059909 – October 22, 1991 – Determination of particle size and electrical charge

5104069 – April 14, 1992 – Apparatus and method for ejecting matter from an aircraft

5110502 – May 5, 1992 – Method of suppressing formation of contrails and solution therefor

5156802 – October 20, 1992 – Inspection of fuel particles with acoustics

5174498 – December 29, 1992 – Cloud Seeding

5148173 – September 15, 1992 – Millimeter wave screening cloud and method

5245290 – September 14, 1993 – Device for determining the size and charge of colloidal particles by measuring electroacoustic effect

5286979 – February 15, 1994 – Process for absorbing ultraviolet radiation using dispersed melanin

5296910 – March 22, 1994 – Method and apparatus for particle analysis

5327222 – July 5, 1994 – Displacement information detecting apparatus

5357865 – October 25, 1994 – Method of cloud seeding

5360162 – November 1, 1994 – Method and composition for precipitation of atmospheric water

5383024 – January 17, 1995 – Optical wet steam monitor

5425413 – June 20, 1995 – Method to hinder the formation and to break-up overhead atmospheric inversions, enhance ground level air circulation and improve urban air quality

5434667 – July 18, 1995 – Characterization of particles by modulated dynamic light scattering

5441200 – August 15, 1995 – Tropical cyclone disruption

5486900 – January 23, 1996 – Measuring device for amount of charge of toner and image forming apparatus having the measuring device

5556029 – September 17, 1996 – Method of hydrometeor dissipation (clouds)

5628455 – May 13, 1997 – Method and apparatus for modification of supercooled fog

5631414 – May 20, 1997 – Method and device for remote diagnostics of ocean-atmosphere system state

5639441 – June 17, 1997 – Methods for fine particle formation

5762298 – June 9, 1998 – Use of artificial satellites in earth orbits adaptively to modify the effect that solar radiation would otherwise have on earth’s weather

5912396 – June 15, 1999 – System and method for remediation of selected atmospheric conditions

5922976 – July 13, 1999 – Method of measuring aerosol particles using automated mobility-classified aerosol detector

5949001 – September 7, 1999 – Method for aerodynamic particle size analysis

5984239 – November 16, 1999 – Weather modification by artificial satellite

6025402 – February 15, 2000 – Chemical composition for effectuating a reduction of visibility obscuration, and a detoxifixation of fumes and chemical fogs in spaces of fire origin

6030506 – February 29, 2000 – Preparation of independently generated highly reactive chemical species

6034073 – March 7, 2000 – Solvent detergent emulsions having antiviral activity

6045089 – April 4, 2000 – Solar-powered airplane

6056203 – May 2, 2000 – Method and apparatus for modifying supercooled clouds

6110590 – August 29, 2000 – Synthetically spun silk nanofibers and a process for making the same

6263744 – July 24, 2001 – Automated mobility-classified-aerosol detector

6281972 – August 28, 2001 – Method and apparatus for measuring particle-size distribution

6315213 – November 13, 2001 – Method of modifying weather

6382526 – May 7, 2002 – Process and apparatus for the production of nanofibers

6408704 – June 25, 2002 – Aerodynamic particle size analysis method and apparatus

6412416 – July 2, 2002 – Propellant-based aerosol generation devices and method

6520425 – February 18, 2003 – Process and apparatus for the production of nanofibers

6539812 – April 1, 2003 – System for measuring the flow-rate of a gas by means of ultrasound

6553849 – April 29, 2003 – Electrodynamic particle size analyzer

6569393 – May 27, 2003 – Method and device for cleaning the atmosphere

Thanks for sharing with us. If anyone required industrial gears then come to Ashoka Group, and get all type of quality gears at competitive rates. We serves industrial gears to almost every industries.

ReplyDeleteJET CLEAN - Manufacturer & Exporter of silver ionization systems, gaseous chlorination plant, automatic water level control system, water testing kit, dosing pump, chlorinator from India

ReplyDelete